We set the standards others try to live up to.

I-Make technology is automotive and other machining component manufacturing company established in 2015. In these years we have diversified in different verticals. We have young, responsible and Technically strong team which helped us to outperform in all verticals. Currently we have good manufacturing facility with advance machine tools

Our Specialties are:

- Expertise in Critical machining Parts

- Hard Part Turning

- Milling parts with 4th axis operations

- Mass production Of bar root Parts

- Complete solution from forging to finished parts

Managing Director

Mr. Abhimanyu D. Patil, (B.E. Mech., M.M.S. Finance) has completed Mechanical Engineering from Government College of Engineering, Aurangabad. Following this he also completed Masters degree in Management studies in Finance.

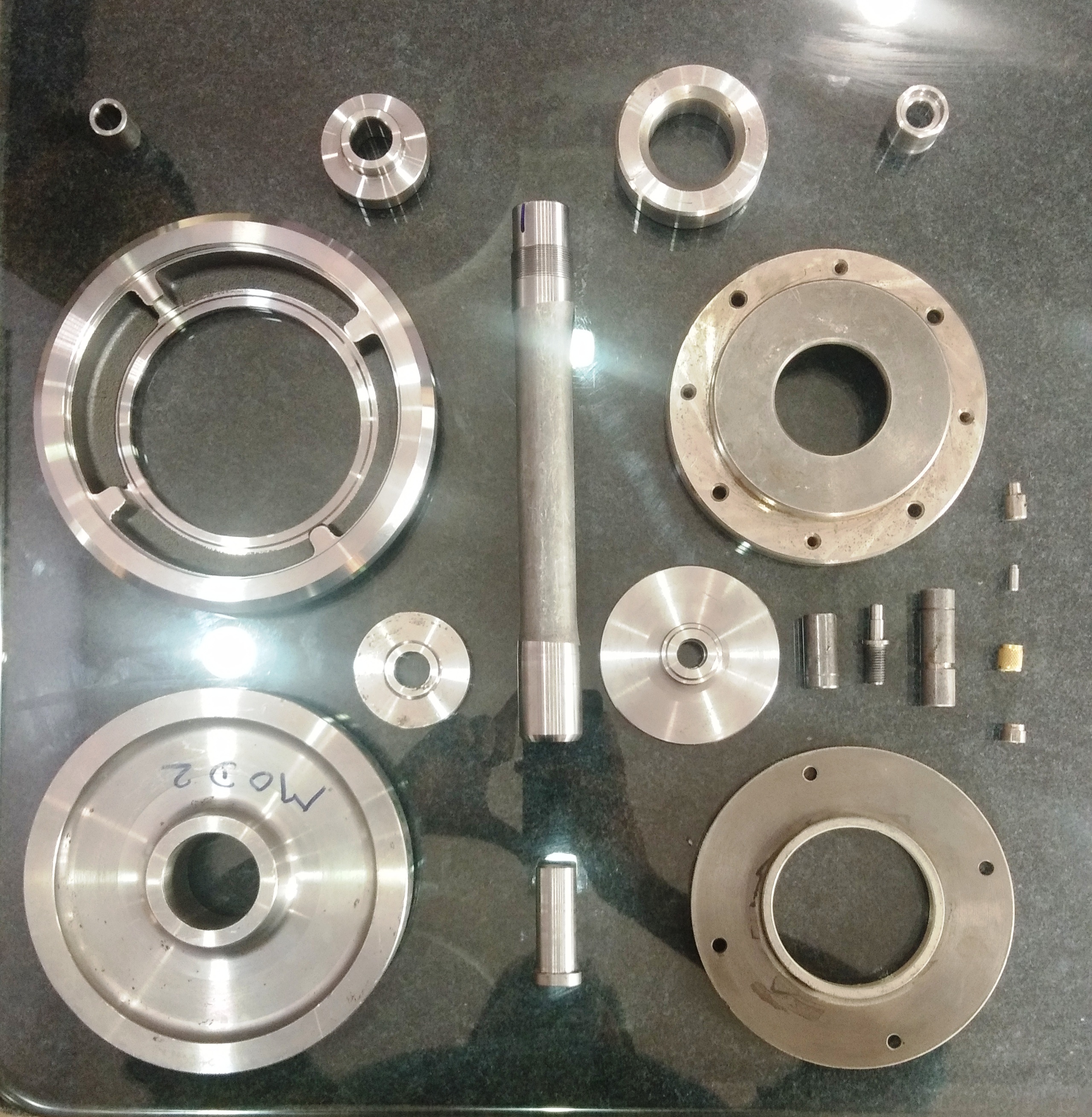

OUR PRODUCTS

_________________________________

Why Choose Us!

WE PROVIDE PROFESSIONAL SERVICES.

VISION

To create an identity as a manufacturer of world class products for improvement of living standards.

MISSION

To achieve highest level of customer satisfaction by delivering quality products globally.

Values

Commitment,Integrity,Team-Work,Innovation.

What People say’s About us

Product Range

_____________________________| 1 | Forged Parts |

| 2 | Gear Blanks |

| 3 | Shaft up to 500 mm Length |

| 4 | Hard Part Turning (60-64 HRC) |

| 5 | Traub Parts, Dowel Pins |

| 6 | Inserts for Aluminum Parts and Plastic Parts |

| 7 | Stainless Steel Parts |

| 8 | Aluminium Parts |

Employees

Experienced supervisor and highly skilled machine shop personnel.Highly motivated and prompt staff familiar with modern quality procedures.

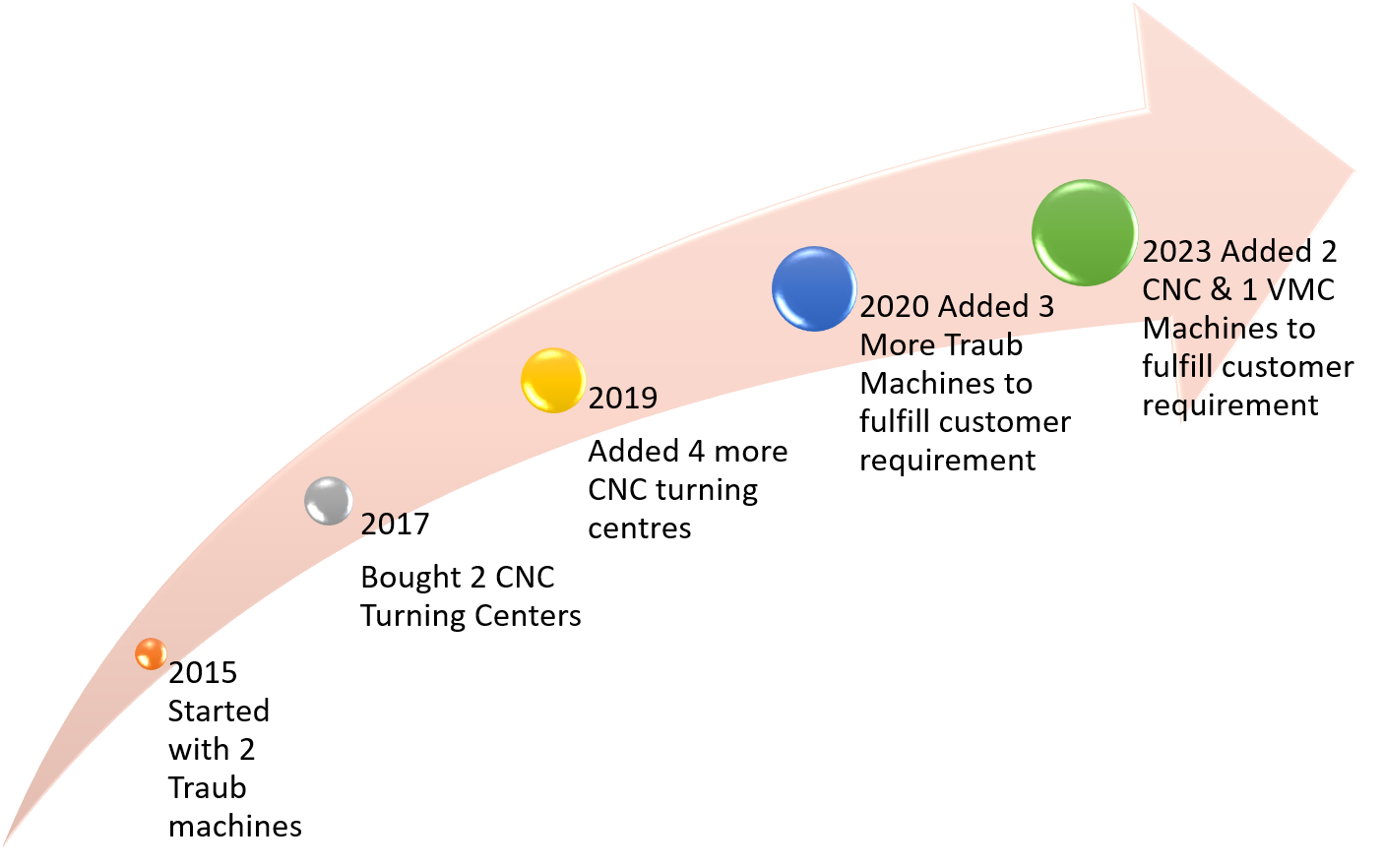

Expansion Trajectory

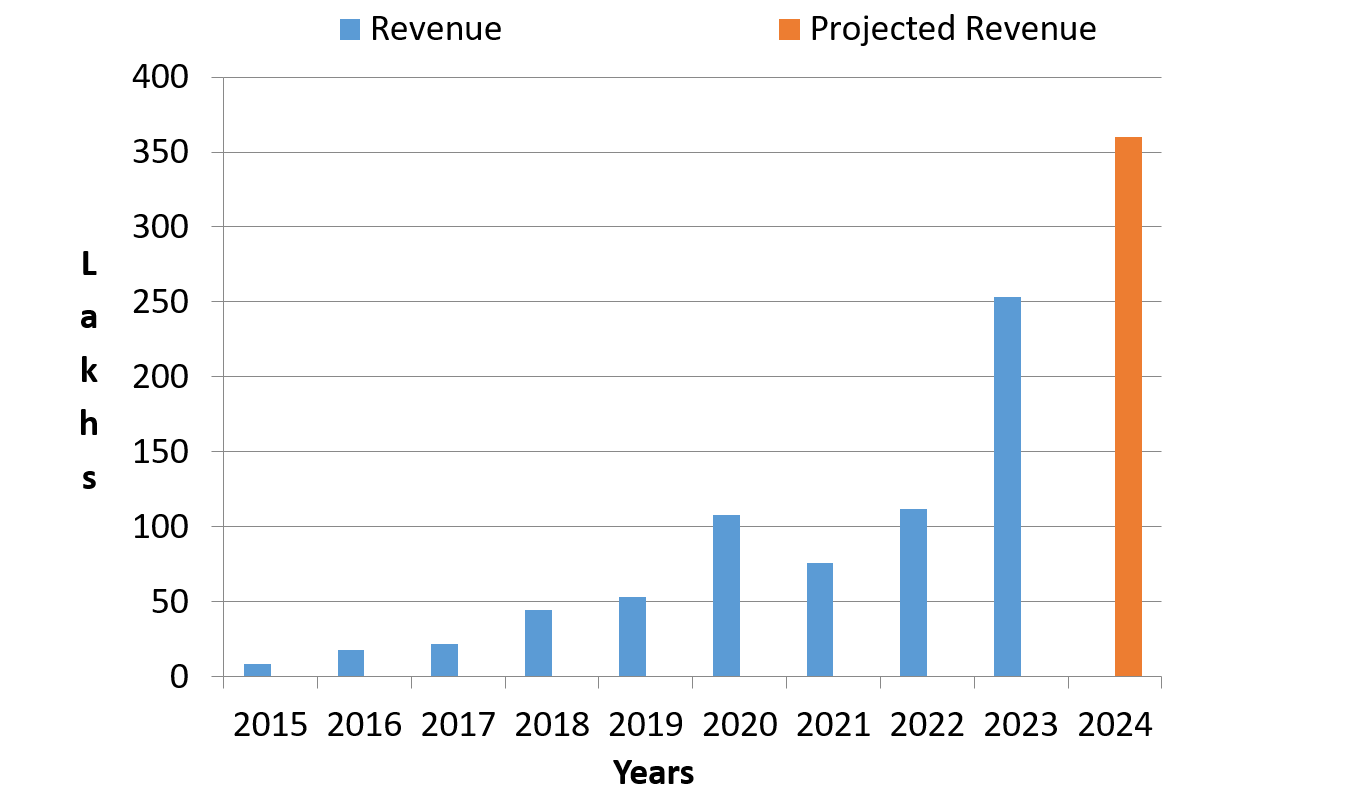

Growth Trajectory

PLANT PHOTOS

______________________Chuck Range Ø165mm To Ø 250 mm & VMC Bed Size 450 X 600

OUR OBJECTIVES

____________To be best Among the equals

To improve quality systems to assure our customer high standards of quality

To adopt new manufacturing technologies to improve our production skills and volume

To continuously strive for inclusive growth

Certifications

We are ISO Certified company QACS International Pvt. Ltd.

- ISO 9001:2015.

- Certificate Number : QAIS-Q-IND-IM-12.23.009

- EA Code: 18 & 22

- Magazine and housed in a nice